Add to Cart

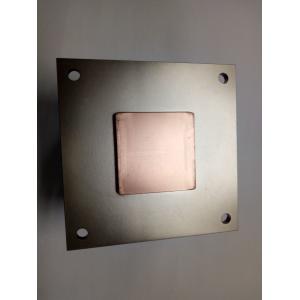

New Design Customized Led Heatsink CPU Cooler High Heat resistant Heatsink

Large Image: Aluminum Fin Heat Sink with Copper Pipe

100W -150w Power Copper Pipe Heat Sink

Copper Pipe Heat Sink for Projector

Heat Sink With Copper Pipe For Projector

This is the new designed heatsink by our selves. The tooling is available. so no need to take extra cost for invested the mold.

Description:

Surface Treatment:Milling plane insert copper

IP Rating:Other

Certification:CE

Place of Origin:Guangdong, China (Mainland)

Brand Name:Huashengyuan

Body Color:Silver

Shape:Square

Body Material:Copper

Application:High-power inverters, power and so on

Application: Projector

Specification:

Overall Dimension: L100*W30*3.6MM

Copper Tube: 8mm in Dia.

Tube Quantity: 3 pcs

Part Weight: 250Gram

Material:

Pure Copper C1100 Strips, Purity over 99.5% (Standard: JIS H3250-2006); Pure Aluminum Board A1060 Purity Over 99.6% .(Standard: GB/T3880-2006).

Little Impurity brings very good Electrical and Heat Conduction; Excellent Performance In Corrosion Resistant as well.

Processing Technic:

1. Copper Fins: Progressive Die Stamping

2. Aluminum Enclosure: Extrusion+ Machining

3. Copper Tube Forming : Automatic Tube Bending+ Burn into Tip Ends.

4. Aluminum Board and Enclosure Nickle Plated, Copper Fin Passivate (Insulation,

Oxidation and Corrosion Resistance).

5. Assembly: Automatic Fin Wearing/Assembly, then Fixed by Overflow Soldering and

Screw/Rivet Combination.

6. Quality Check

7. Packing

Advantages:

1. Professional Research and Design Team, Strong & Automatic Equipments: Progressive

Stamping, Automatic Tube Bending Machine, Automatic Fin Wearing Machining

2. Strict Quality Control in Each Process and Finish Product Quality Control

3. Short Delivery Lead Time: 15-30 Days

4. Optional For OEM or ODM

5. Comprehensive After-Sale Service, Quick Responses For Daily Communication