Add to Cart

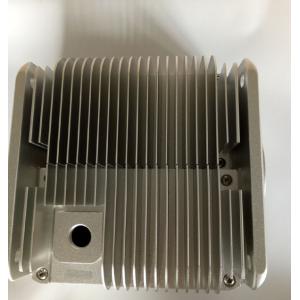

Aluminium Die Casting Parts Machined parts High Disspation For LED Lighting Base

Quick Details:

Precision Aluminum die casting & Aluminum casting

Large Image: Transmission Housing For Golf Cart, Club Car and Caddy

Surface Treatment: Sand Blasting

Depend on customer's requirements

Description:

Large Image: Transmission Housing for Golf Cart,

Transmission Housing for Club Car,

Transmission Housing for Caddy

Application:

LED Fixtures, Led lighting

Specification:

| Overall Dimension | L400*W250*H150mm |

| Surface Treatment | Die casting |

| Part Weight | 3.0kgs |

| Material | ADC12(Standard: JIS H 5302-2000) |

Facility:

Die Casting Workshop

Die Casting Workshop

Processing Technic:

1. Die Casting Tooling Making--Prototype/T1--Dimension Check-- Sample Approval-- SOP

2. Die Casting-- Remove Water Gap--Deburring-- Machining--Dilling Holes/ Threading-- Quality Check (dimension and STEAM TIGHT TEST)-- Sanding Blasting --QC (Surface Vision Checking)-- Packing

Advantages:

1. Professional Research and Design Team (20 Persons), Possess All Necessary Equipments.

2. Strict Quality Control in Each Process and Finish Product Quality Control

3. Short Delivery Lead Time: 15-30 Days

4. Optional For OEM or ODM

5. Comprehensive After-Sale Service, Quick Responses For Daily Communication