Add to Cart

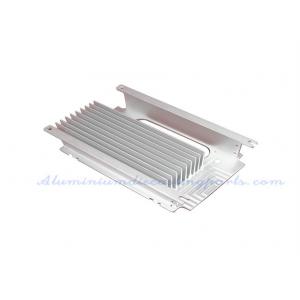

Aluminum Extruded Heat Sink For Consumer Electronic Product

Application: For Solar Energy Equipment

Specification:

| Overall Dimension | L250*W160*H60mm |

| Surface Treatment | Silver Anodize (Anodized Film Thickness > 12 microns |

| Part Weight | 2.5kgs |

Material: Al6063 T6

Type of Aluminum Alloy 6063 brings very good Heat dissipation; Excellent Performance In Corrosion

Resistant after anodize as well.

Processing Technic:

Check (dimension and surface) -- Acid Washing-- Black Anodize -- FQC (Surface Vision

Checking)-- Packing

3. Brush Finish Brings Very High End Surface Looking and Good Feeling For Touching.

Facility:

Extrusion Workshop

CNC Machining

2nd Machining (Drill holes/Threading)

Advantages:

Professional Research and Design Team, Processes All Necessary Equipments: Extrusion Machine:

2 Sets; CNC Machine: 10 Sets (Maximum working platform: 1200*80),

Drill/threading machining: 25 Machines